Compressed gas cylinders are a common fixture in research laboratories. As such it is imperative to understand the safe handling, transportation, and use of compressed gas cylinders. Compressed gas is defined by the Occupational Health and Safety Administration (OSHA) per 29 CFR 1910.1200 as :

A gas or mixture of gases having, in a container, an absolute pressure exceeding 40 psi at 70 deg. F (21.1 deg. C); or a gas or mixture of gases having, in a container, an absolute pressure exceeding 104 psi at 130 deg. F (54.4 deg. C) regardless of the pressure at 70 deg. F (21.1 deg. C); or a liquid having a vapor pressure exceeding 40 psi at 100 deg. F (37.8 deg. C) as determined by ASTM D-323-72.

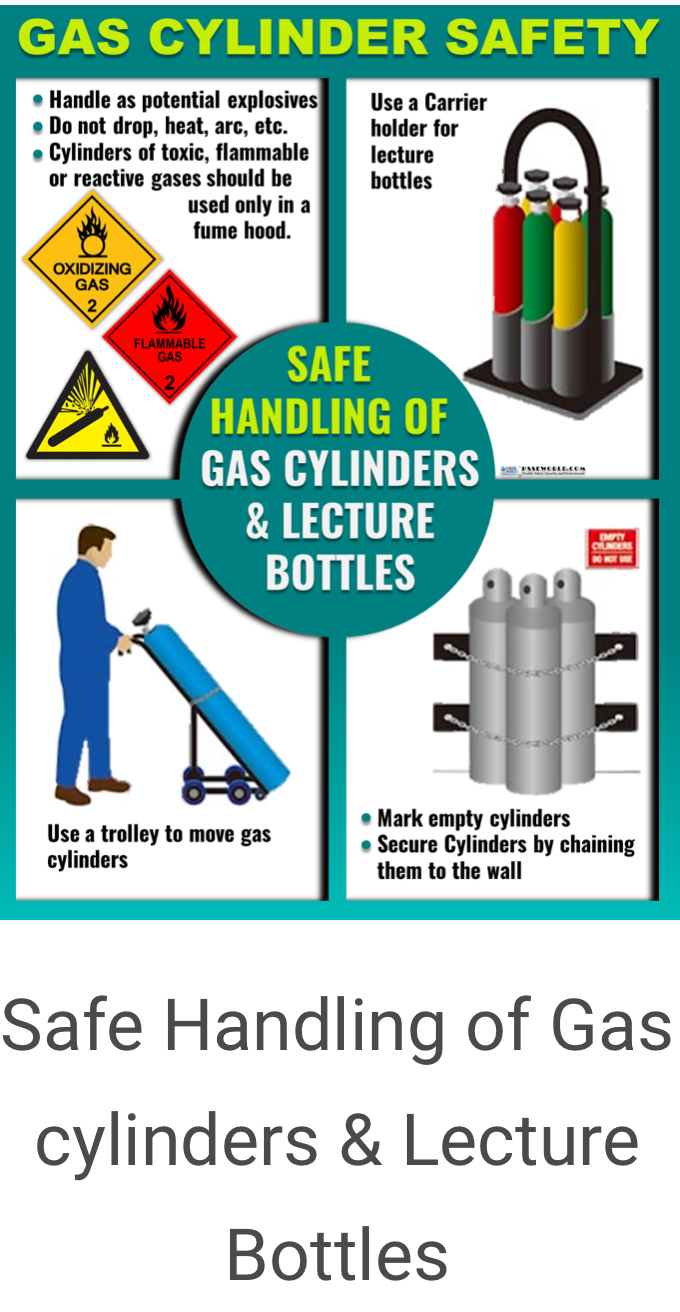

The broad definition provided by OSHA makes it difficult to cover all prudent practices concerning compressed gas safety. Therefore, the scope of this document will address compressed gas cylinders that are common in a laboratory environment. in the photo of today you will be familiar with the safe use and handling of compressed gas cylinders and lecture bottles with the free download of four posters.

Also read : FM-200 System -Fire Suppression Agent (Gas System )

SAFE HANDLING AND USAGE ( Gas Cylinder )

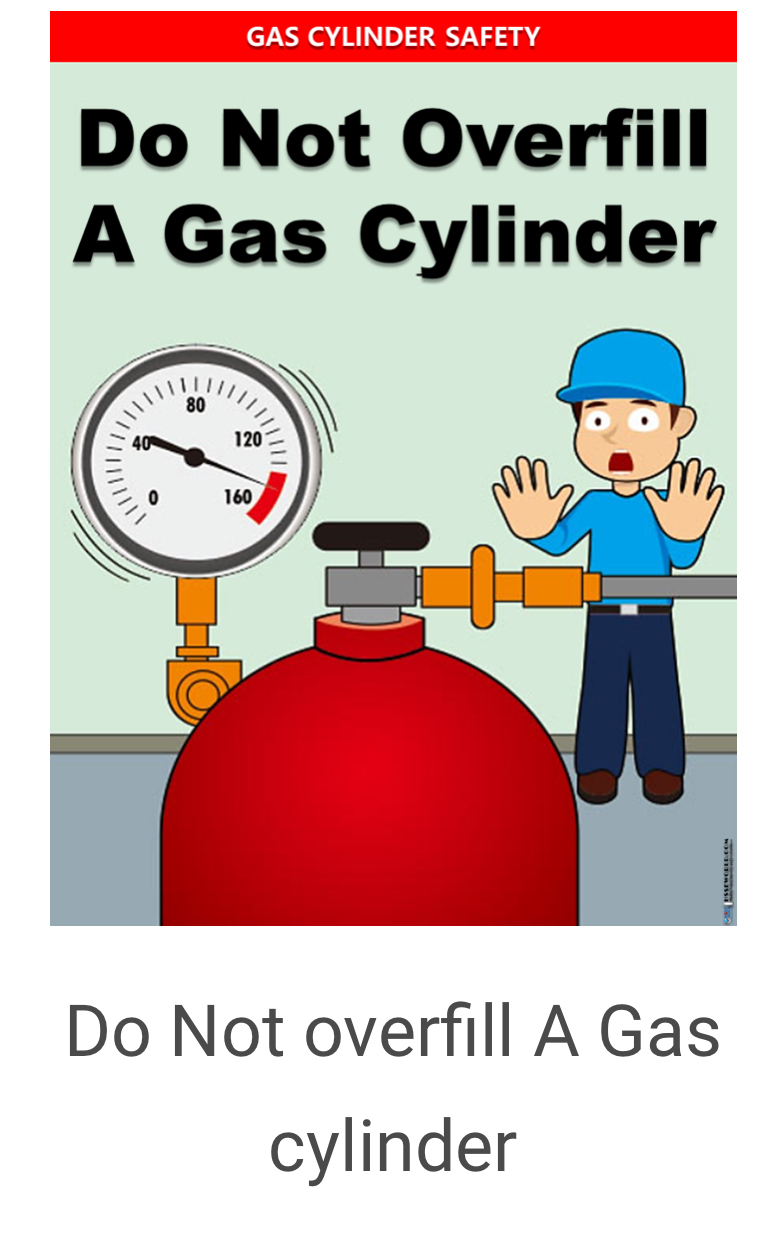

Most compressed gas cylinders, whether they are ultra-high purity or industrial grade, will be pressurized to around 2000 psi. This represents an enormous amount of potential energy. If the gas is released uncontrollably or over-pressurizes equipment, there is an immediate hazard to life and health. Furthermore, many compressed gas cylinders will contain flammable or toxic gas. Finally, the threat of asphyxiation due to oxygen displacement by the release of compressed gas must also be considered.

Always review manufacturers’ Safety Data Sheet (SDS) before using compressed gas for specific personal protective equipment, usage, and storage guidelines.

TRACKING:

- When receiving compressed gases from the manufacturer or a distributor, record the prudent information in the OSU online chemical inventory that is part of the Chemical Safety Assistant.

- It is also good practice to record the general timeframe a cylinder will be used. This will help minimize cylinder rental fees and prevent the accumulation of unneeded cylinders.

- All compressed gas cylinders must be returned to the supplier when empty or no longer in use.

- Appropriately label empty cylinders as being empty.

Also Read : CO2-System Gas Cylinder.

STORAGE:

|

| Figure 1. The figure depicts proper compressed gas cylinder |

- Cylinders must be secured with an appropriate strap or chain when in storage, transit, or use. Secure cylinders by firmly chaining or strapping them to a wall, lab bench, or other fixed support. See Figure 1.

- Valve protection caps must be in place during transit or storage. The only time the cap should be removed is while it’s being used.

- Cylinders must be stored in an upright position.

- Never allow storage temperature to exceed 125°F (52°C).

- Never permit smoking or open flames in oxidizer or flammable gas storage areas.

- Oxygen should be stored in an area that is at least 20 feet away from any flammable or combustible materials (including gases) or separated from combustibles by a non-combustible barrier at least 5 feet high and having a fire-resistance rating of at least 1/2 hour.

- Never expose cylinders to corrosive materials.

- Segregate full and empty cylinders.

- Store cylinders in a dry, cool, well-ventilated, secure area that is protected from the weather and away from combustible materials.

- Store cylinders away from heavily traveled areas and emergency exits.

- Visually inspect stored cylinders on a weekly basis for any indication of leakage or problems.

- Protect cylinders from the wet or damp ground.

LECTURE BOTTLES

- Especially hazardous lecture bottles may require ventilated storage in a gas cabinet or exhausted enclosure. Refer to Table 1 for storage guidelines.

- Designated areas should be assigned in the lab for lecture bottle storage. Areas should be labeled for lecture bottle storage according to hazard class. Due to the small nature of lecture bottles, they are often stored in random areas which makes them easily misplaced.

- Outdated lecture bottles containing corrosive gas pose a significant explosion hazard.

- Store lecture bottles upright and segregated according to hazard class.

- Remove regulators and replace protective caps or plugs when lecture bottles are not in use.

- Lecture bottles must be properly secured during use, and lecture bottles containing hazardous gases (corrosive or poison) must be used in a fume hood or gas cabinet.

- Lecture bottles must be properly labeled. Re-label the lecture bottle if the label becomes illegible or falls off. It is a good idea to also label the regulator with the gas it was last used for to prevent accidental misuse in the future.

- When purchasing lecture bottles, the manufacturer’s return policy should be considered. The disposal cost of a lecture bottle may exceed the difference in the purchase price. It is best to purchase lecture bottles from vendors that will allow the return of the bottle.

- Inspect the lecture bottle and regulator prior to use. Never use lecture bottles or regulators that are damaged or corroded.

Safety Gas Cylinders Posters

|

| Safe Handling of Gas Cylinders and Lecture Bottles |

Also Read : Industrial Fire Protection Handbook

Also Read: Fire Protection of Buildings

0 Comments