Chiller Plant Design: Using Chilled Water to cool a building or process is efficient and flexible. A two inch schedule 40 pipe of chilled water can supply as much comfort cooling as 42" diameter round building location or even on the roof and distribute the water economically and without the use of large duct shafts.

|

| Chiller Plant Design |

Chiller Plant Design

Table of Contents

- Introduction

- Chiller Basics

DOWNLOAD also HVAC Calculator , A Free Software Psychrometric Analyzer

Piping Basics

Pumping Basics

Cooling Tower Basics

Load Basics

Control Valve Basics

Loop Control Basics

Piping Diversity

- Water Temperatures and Ranges

Supply Air Temperature

Chilled Water Temperature Range

Condenser Water Temperature Range

Temperature Range Trends

- Air and Evaporatively Cooled Chillers

Air-Cooled Chillers

Evaporatively Cooled Chillers

- Dual Compressor and VFD Chillers

Dual Compressor Chillers

VFD Chillers

System Design Changes

- Mechanical Room Safety

- Single Chiller System

Basic Operation

Basic Components

Single Chiller Sequence of Operation

- Parallel Chiller System

Basic Operation

Basic Components

Parallel Chiller Sequence of Operation

- Series Chillers

Basic Operation

Basic Components

Series Chillers Sequence of Operation

Series Counterflow Chillers

Using VFD Chillers in Series Arrangements

System Comparison

Application Guide AG 31-003-1 3

Basic Operation

Basic Components

Very Large Chiller Plants

Primary/Secondary Sequence of Operation

DOWNLOAD also HVAC Calculator , A Free Software Psychrometric Analyzer

- Water-Side Free Cooling

Direct Waterside Free Cooling

Parallel Waterside Free Cooling

Series Waterside Free Cooling

Waterside Free Cooling Design Approach

Waterside Free Cooling Sequence of Operation

Economizers and Energy Efficiency

- Hybrid Plants

- Heat Recovery and Templifiers™

General

Load Profiles

Heat Recovery Chillers

Templifiers™

ASHRAE Standard 90.1

- Variable Primary Flow Design

- Low Delta T Syndrome

- Process Applications

- Minimum Chilled Water Volume

Introduction

Using Chilled Water to cool a building or process is efficient and flexible. A two inch schedule 40 pipe of chilled water can supply as much comfort cooling as 42" diameter round building location or even on the roof and distribute the water economically and without the use of large duct shafts. Chilled water also provides accurate temperature control that isespecially useful for VAV applications.

The purpose of this manual is discuss various piping and control strategies commonly used with chilled water systems including variable flow pumping systems.

Basic System

Figure 1 shows a basic chiller loop with a water-cooled chiller. The system consists of a chiller, cooling tower, building cooling load, chilled water and condensing water pumps and piping. Thissection will review each of the components.

Figure 1 - Single Chiller Loop

Chiller Basics

The Chiller can be water-cooled, air-cooled or evaporatively cooled. The compressor types typically are reciprocating, scroll, screw or centrifugal. The evaporator can be remote from the condensing section on air-cooled units. This has the advantage of allowing the chilled water loop to remain inside the building envelope when using an outdoor chiller. In applications where freezing conditions can be expected, keeping the chilled water loop inside the building avoids the need for some form of antifreeze. There can be multiple chillers in a chilled water plant. The details of various multiple chiller plant designs will be discussed in future sections. The chilled water flows through the evaporator of the chiller. The evaporator is a heat exchanger where the chilled water gives up its sensible heat (the water temperature drops) and transfers the heat to the refrigerant as latent energy (the refrigerant evaporates or boils).

Flow and Capacity Calculations

For air conditioning applications, the common design conditions are 44°F supply water temperature and 2.4 gpm/ton.The temperature change in the fluid for either the condenser or the evaporator canbe described using the following formula:

Assuming the fluid is water, the formula takes the more common form of:Using this equation and the above design conditions, the temperature change in the evaporator is found to be 10°F. The water temperature entering the evaporator is then 54°F. Most air conditioning design conditions are based on 75°F and 50% relative humidity (RH) in the occupied space.The dewpoint for air at this condition is 55.08°F. Most HVAC designs are based on cooling the air to this dewpoint to maintain the proper RH in the space. Using a 10°F approach at the cooling coil means the supply chilled water needs to be around 44°F or 45°F.The designer is not tied to these typical design conditions. In fact, more energy efficient solutions can be found by modifying the design conditions, as the project requires. Changing the chilled water flow rate affects a specific chiller's performance.Too low a flow ratelowers the chiller efficiency and ultimately leads to laminar flow. The minimum flow rate is typically around 3 fps (feet per second). Too high a flow rate leads to vibration, noise and tube erosion.The maximum flow rate is typically around 12 fps. The chilled water flow rate should be maintained between these limits of 3 to 12 fps.The condenser water flows through the condenser of the chiller. The condenser is also a heat exchanger. In this case the heat absorbed from the building, plus the work of compression, leaves the refrigerant (condensing the refrigerant) and enters the condenser water (raising its temperature).The condenser has the same limitations to flow change as the evaporator.

Chillers and Energy Efficiency

Chillers are often the single largest electricity users in a building. A 1000 ton Chiller has a motor rated at 700 hp. Improving the chiller performance has immediate benefit to the building operating cost.Chiller full load efficiency ratings are usually given in the form of kW/ton, COP (Coefficient of Performance = kWcooling / kWinput) or EER (Energy Efficiency Ratio = Tons X 12/ kWinput). Full load performance is either the default ARI conditions or the designer specified conditions. It is important to be specific about operating conditions since chiller performance varies significantly at different operating conditions.Chiller part load performance can be given at designer-specified conditions or the NPLV (NonStandard Part Load Value) can be used. The definition of NPLV is spelled out in ARI 550/590-98,

Test Standard for Chillers.For further information refer to McQuay Application Guide AG 31-002,

Centrifugal Chiller Fundamentals.

Figure 2 - ASHRAE Std 90.1 Chiller Performance Table1

Since buildings rarely operate at design load conditions (typically less than 2% of the time) Chiller.part load performance is critical to good overall chiller plant performance. Chiller full and part load.efficiencies have improved significantly over the last 10 years (Chillers with NPLVs of 0.35 kW/ton are available) to the point where future chiller plant energy performance will have to come from Chiller Plant Design.ASHRAE Standard 90.1-2001 includes mandatory requirements for minimum Chiller performance.Table 6.2.1.C of this standard covers chillers at ARI standard conditions. Tables 6.2.1H to M cover centrifugal chillers at non-standard conditions.

Figure 1 shows a basic chiller loop with a water-cooled chiller. The system consists of a chiller, cooling tower, building cooling load, chilled water and condensing water pumps and piping. Thissection will review each of the components.

Figure 1 - Single Chiller Loop

Chiller Basics

The Chiller can be water-cooled, air-cooled or evaporatively cooled. The compressor types typically are reciprocating, scroll, screw or centrifugal.

The evaporator can be remote from the condensing section on air-cooled units. This has the advantage of allowing the chilled water loop to remain inside the building envelope when using an outdoor chiller. In applications where freezing conditions can be expected, keeping the chilled water loop inside the building avoids the need for some form of antifreeze.

There can be multiple chillers in a chilled water plant. The details of various multiple chiller plant designs will be discussed in future sections.

The chilled water flows through the evaporator of the chiller. The evaporator is a heat exchanger where the chilled water gives up its sensible heat (the water temperature drops) and transfers the heat to the refrigerant as latent energy (the refrigerant evaporates or boils).

Flow and Capacity Calculations

For air conditioning applications, the common design conditions are 44°F supply water temperature and 2.4 gpm/ton.

The temperature change in the fluid for either the condenser or the evaporator can

be described using the following formula:

Assuming the fluid is water, the formula takes the more common form of:

Using this equation and the above design conditions, the temperature change in the evaporator is found to be 10°F. The water temperature entering the evaporator is then 54°F. Most air conditioning design conditions are based on 75°F and 50% relative humidity (RH) in the occupied space.

The dewpoint for air at this condition is 55.08°F. Most HVAC designs are based on cooling the air to this dewpoint to maintain the proper RH in the space. Using a 10°F approach at the cooling coil means the supply chilled water needs to be around 44°F or 45°F.

The designer is not tied to these typical design conditions. In fact, more energy efficient solutions can be found by modifying the design conditions, as the project requires. Changing the chilled water flow rate affects a specific chiller's performance.

Too low a flow ratelowers the chiller efficiency and ultimately leads to laminar flow. The minimum flow rate is typically around 3 fps (feet per second). Too high a flow rate leads to vibration, noise and tube erosion.

The maximum flow rate is typically around 12 fps. The chilled water flow rate should be maintained between these limits of 3 to 12 fps.

The condenser water flows through the condenser of the chiller. The condenser is also a heat exchanger. In this case the heat absorbed from the building, plus the work of compression, leaves the refrigerant (condensing the refrigerant) and enters the condenser water (raising its temperature).

The condenser has the same limitations to flow change as the evaporator.

Chillers and Energy Efficiency

Chillers are often the single largest electricity users in a building. A 1000 ton Chiller has a motor rated at 700 hp. Improving the chiller performance has immediate benefit to the building operating cost.

Chiller full load efficiency ratings are usually given in the form of kW/ton, COP (Coefficient of Performance = kWcooling / kWinput) or EER (Energy Efficiency Ratio = Tons X 12/ kWinput).

Full load performance is either the default ARI conditions or the designer specified conditions. It is important to be specific about operating conditions since chiller performance varies significantly at different operating conditions.

Chiller part load performance can be given at designer-specified conditions or the NPLV (NonStandard Part Load Value) can be used. The definition of NPLV is spelled out in ARI 550/590-98,

Test Standard for Chillers.

For further information refer to McQuay Application Guide AG 31-002,

Centrifugal Chiller Fundamentals.

Figure 2 - ASHRAE Std 90.1 Chiller Performance Table1

Since buildings rarely operate at design load conditions (typically less than 2% of the time) Chiller.

part load performance is critical to good overall chiller plant performance. Chiller full and part load.

efficiencies have improved significantly over the last 10 years (Chillers with NPLVs of 0.35 kW/ton are available) to the point where future chiller plant energy performance will have to come from Chiller Plant Design.

ASHRAE Standard 90.1-2001 includes mandatory requirements for minimum Chiller performance.

Table 6.2.1.C of this standard covers chillers at ARI standard conditions. Tables 6.2.1H to M cover centrifugal chillers at non-standard conditions.

Piping Basics

Closed Loop

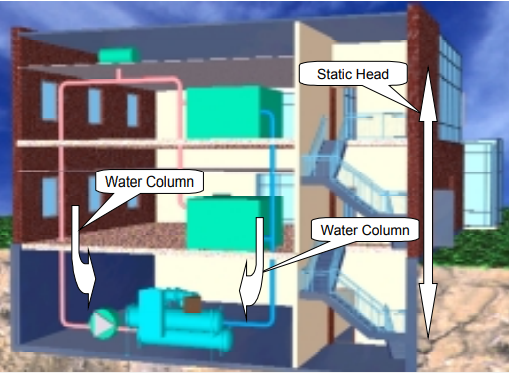

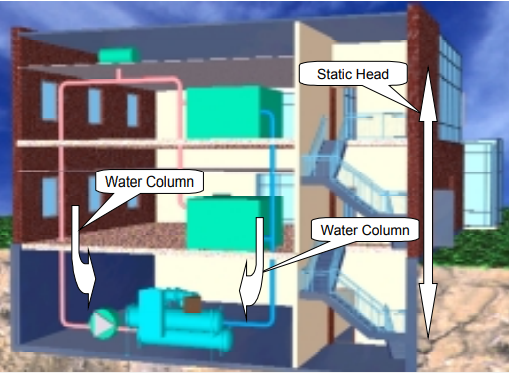

The piping is usually steel, copper or plastic. The chilled water piping is usually a closed loop. A closed loop is not open to the atmosphere. Figure 3 shows a simple closed loop with the pump at the bottom of the loop. Notice that the static pressure created by the change in elevation is equal on both sides of the pump. In a closed loop, the pump needs only to overcome the friction loss in the piping and components. The pump does not need to “lift” the water to the top of the loop.

When open cooling towers are used in condenser piping, the loop is an open type. Condenser pump must overcome the friction of the system and “lift” the water from the sump to the top of the cooling tower. Figure 4 shows an open loop. Notice the pump need only overcome the elevation difference of the cooling tower, not the entire building.

In high-rise applications, the static pressure can become considerable and exceed the pressure rating of the piping and the components such as chillers. Although chillers can be built to higher pressure ratings (The standard is typically 150 PSI but the reader is advised to check with the manufacturer) high pressure systems can become expensive. The next standard rating is typically 300 PSI. Above that, the chillers become very expensive. One solution is to use heat exchangers to isolate the chillers from the static pressure. While this solves the pressure rating for the chiller, it introduces another device and another approach that affects supply water temperature and chiller performance. A second solution is to locate chiller plants on various floors throughout the building selected to avoid exceeding the 150 PSI chiller rating.

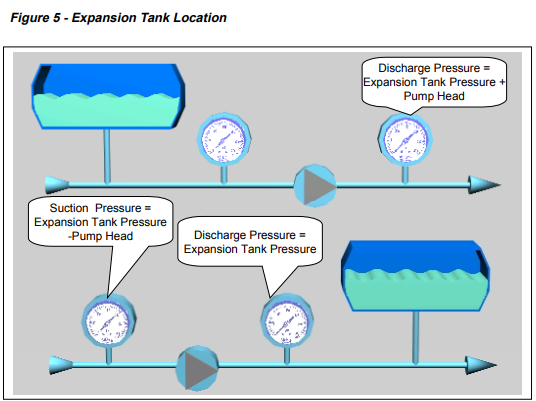

Expansion Tanks

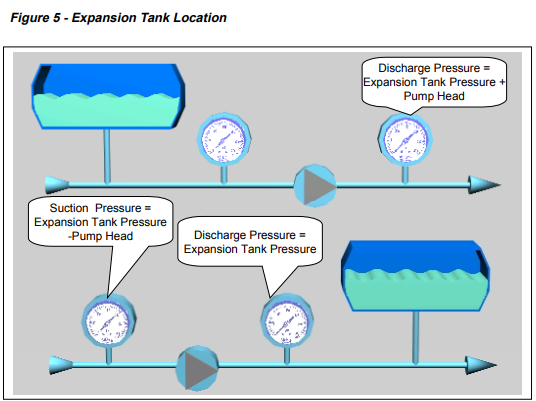

An Expansion Tank is required in the Chilled Water loop to allow for the thermal expansion of the water. Expansion tanks can be open type, closed type with air-water interface or diaphragm type. Tank location will influence the type. Open tanks must be located above the highest point in the system (for example, the penthouse). Airwater interface and diaphragm type tanks can be located anywhere in the system. Generally, the lower the pressure in the tank, the smaller the tank needs to be. Tank size can be minimized by locating it higher in the system.

Expansion Tank

The pressure at which the tank is operated is the reference point for the entire hydronic system. The location of the tank -which side on the pump (suction or discharge) - will affect the total pressure seen by the system. When the pump is off, the tank will be exposed to the static pressure plus the pressure due to thermal expansion. If the tank is located on the suction side, when the pump is running, the total pressure seen on the discharge side will be the pressure differential, created by the pump, added to the expansion tank pressure. If the expansion tank is located on the discharge side of the pump, the discharge pressure will be the same as the expansion tank pressure and the suction side pressure will be the expansion tank pressure minus the pump pressure differential.

DOWNLOAD Chiller Plant Design handbook.

The piping is usually steel, copper or plastic. The chilled water piping is usually a closed loop. A closed loop is not open to the atmosphere. Figure 3 shows a simple closed loop with the pump at the bottom of the loop.

Notice that the static pressure created by the change in elevation is equal on both sides of the pump. In a closed loop, the pump needs only to overcome the friction loss in the piping and components. The pump does not need to “lift” the water to the top of the loop.

When open cooling towers are used in condenser piping, the loop is an open type.

Condenser pump must overcome the friction of the system and “lift” the water from the sump to the top of the cooling tower. Figure 4 shows an open loop. Notice the pump need only overcome the elevation difference of the cooling tower, not the entire building.

In high-rise applications, the static pressure can become considerable and exceed the pressure rating of the piping and the components such as chillers. Although chillers can be built to higher pressure ratings (The standard is typically 150 PSI but the reader is advised to check with the manufacturer) high pressure systems can become expensive. The next standard rating is typically 300 PSI. Above that, the chillers become very expensive. One solution is to use heat exchangers to isolate the chillers from the static pressure. While this solves the pressure rating for the chiller, it introduces another device and another approach that affects supply water temperature and chiller performance. A second solution is to locate chiller plants on various floors throughout the building selected to avoid exceeding the 150 PSI chiller rating.

An Expansion Tank is required in the Chilled Water loop to allow for the thermal expansion of the water. Expansion tanks can be open type, closed type with air-water interface or diaphragm type. Tank location will influence the type. Open tanks must be located above the highest point in the system (for example, the penthouse). Airwater interface and diaphragm type tanks can be located anywhere in the system. Generally, the lower the pressure in the tank, the smaller the tank needs to be. Tank size can be minimized by locating it higher in the system.

|

| Expansion Tank |

The pressure at which the tank is operated is the reference point for the entire hydronic system. The location of the tank -which side on the pump (suction or discharge) - will affect the total pressure seen by the system. When the pump is off, the tank will be exposed to the static pressure plus the pressure due to thermal expansion. If the tank is located on the suction side, when the pump is running, the total pressure seen on the discharge side will be the pressure differential, created by the pump, added to the expansion tank pressure. If the expansion tank is located on the discharge side of the pump, the discharge pressure will be the same as the expansion tank pressure and the suction side pressure will be the expansion tank pressure minus the pump pressure differential.

DOWNLOAD Chiller Plant Design handbook.