Fire Fighting System

- Water system ( sprinkler system & FHC & FH )

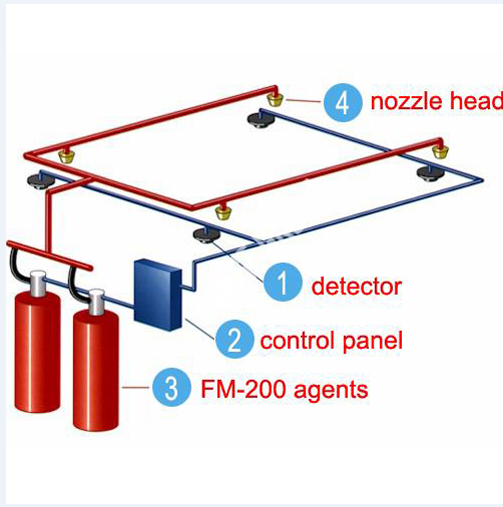

- GAS SYSTEM ( FM200 & CO2 &FOAM )

Definitions

What is the Fire ?

A process in which substance combines chemically with oxygen from the air and typically give out bright, heat and smoke, combustion or burning .

FIRE CAUSES

Fires start when a flammable MATERIAL , in combination with a sufficient quantity of an oxidizer ( AIR ) exposed to a source of HEAT

FIRE TRIANGLE

HOW TO SUPPRESS FIRE?

To avoid or suppress fire, One of the FIRE TRIANGLE side should be eliminated .

- The most applicable side is TO COOL THE AREA TO AVOID HEAT ( WATER SPRINKLER SYSTEM - FIR STANDPIPE SYSTEM ).

- Or to Decrease the percentage of oxidizer around the material (GAS Suppression system CO2-FM200-FOAM NOVEC ,,,etc )

- COST OF WATER SPRINKLER SYSTEM IS less than CO2, IS less than FM-200.

CODES &Standards

- NATIONAL FIRE PROTECTION ASSOCIATION ( NFPA )

- American National Standard Institute (ANSI).

- American Society Mechanical Engineer ( ASME ) .

- American Society for Testing and Materials ( ASTM )

- Underwriters Laboratories Inc.(UL). STANDARD

- Factory Mutual (FM). STANDARDS

UL Standards development covers more than just products, it also includes testing of systems and services . and while we are widely known for our work with safety standards , UL develops a wide variety of standards to measure and validate performance , environmental health and sustainability .

FM Approvals certifies products and services with a unique focus on Objectively testing property loss prevention products and services and certifying those that meet rigorous loss prevention standards .

Encouraging the development and use of FM Approved products and services that improve and advance property loss prevention

Most Important NFPA Chapters

- NFPA 10 Standard for portable Fire Extinguishers.

- NFPA 11 Standard for Expansion Foam .

- NFPA 12 Standard on Carbon Dioxide Extinguishing System.

- NFPA 13 Standard for the Installation of Sprinkler Systems

- NFPA14 Standard for Installation of Standpipe and Hose System.

- NFPA 17 Standard for Dry Chemical Extinguishing Systems

- NFPA20 Standard for the Installation of Stationary Pump for Fire Protection .

HAZARDS CLASSIFICATION

Occupancy hazard classification is the most critical aspect of the sprinkler system design process .

If the hazard is underestimated, it is possible for fire to over power the sprinklers (resulting in a large loss of property or life )

The classification of hazard varies according to the commodities and application of the project .

- Light Hazard

- Ordinary Hazard Group (1)

- Ordinary Hazard Group (2)

- Extra Hazard Group (1)

- Extra Hazard Group (2)

Light Hazard

light hazard occupancies shall be defined as occupancies or portions of other occupancies where the quantity and / or combustibility of contents is low and fires with relatively low rates of heat release are expected .

Ordinary hazard (group 1 )

- Ordinary hazard (group 1) occupancies shall be defined as occupancies where combustibility is low, quantity of combustibles is moderate.

- Stockpiles of combustibles do no exceed 8 ft (2.4 m) and fire with moderate rates of heat release are expected .

Ordinary hazard ( group 1) examples

Ordinary hazard ( group 2 )

- Occupancies shall be defined as occupancies or portions of other occupancies where the quantity and combustibility of contents are moderate to high

- Stockpiles do not exceed 12 ft (3.7 m) and fire with moderate to high rates of heat release are expected

- Stockpiles do not exceed 12 ft (3.7 m), and fires with moderate to high rates of heat release are expected.

Ordinary hazard ( group 2 ) examples

Extra hazard (group 1)

Extra hazard (group 1) occupancies shall be define as occupancies or portions of other occupancies where the quantity and combustibility of contents are very high and dust, lint, or ohet material are present, introducing the probability of rapidly developing fire with high rates of heat release but with little or no combustible or flammable liquid.

Extra hazard ( grond 1) examples

Extra hazard (group 2)

Extra hazard (group 2) occupancies shall be defined as occupancies or portions of other occupancies with moderate to substantial amounts of flammable or combustible liquids or occupancies where shielding of combustibles is extensive.

Extra hazard (group 2) examples

Fire fighting net work components

- Water source & pumping

- Pipe type & connection of pipe

- Pipe accessories & valves

- Stand pipe systems ( Manual system )

Water source

The main source of fire fighting water is water tanks ( Under / Above ground )

Water tank

Pipe type

- Black steel

- Galvanized steel

- H.D.P.E high density polyethylene

- U.P.V.C (Poly vinyl chloride )

Steel pipe galvanization

Protection of steel pipe

Black steel pipe opening

Fire fighting pipe routing

Routing of fire fighting pipes would be :

- Above ground

- Buried under ground

Depth of under ground pipe

Steel pipe dimensions

Connection of fir fighting pipes

Fire fighting steel pipes are being connected by:

- Threaded connection.

- Welding connection

- Grooved coupling connection (most expensive)

Threaded connections

Welding connection

Grooved coupling connection

Pipe flanges

Connection of plastic pipes

Pipe Accessories & Valves under ground pipe supports

- Under ground pipes should be supported wherever were placed under ground

- Pipe should be supported along it is full length .

- Elbows,Tees, and other fittings should be supported on thrust blocks.

- Sleeves should be placed wherever required

Pipe Accessories

Under ground pipe accessories

Above ground pipe

Pipe hanger and support

Common types of acceptable hangers

Maximum distance between hangers

Rode side

Sectional Valves

Sectional

valves are used to separate specific parts of the fire fighting net work for

maintenance and repair times

- Approved self - indicating valves only should be used for sectional valves

- Valves should be automatically supervised (Electrically/Mechanically)

- Shall be of the type that does not totally close in less than 5 seconds to prevent water hammer occurrence .

- should be 12 m away from the building being protected

Sectional Valves

OS& Y Gate valve

Butter fly valve

Automatic Air Vent

Automatic air vent should be placed at the highest points of the net work to vent the air exists inside the pipe.

Drain Valve

Drain valve should be placed at the lowest point of the fire fighting net work to drain the water net work for washing & maintenance of the pipe

Check Valve

Pressure relief valve

- Pressure relief valve is designed specifically to automatically relieve excess pressure in fire protection piping system

- It maintains constant system pressure within very close limits as demands change.

Expansion joint

Flushing of fir fighting pipe

Fire fighting pipes should be flushed aginst contaminations and waste solid materials

Testing of pipes

- Fire fighting pipes should be tested after installation at site to ensure durability of the system

- All pipes , fittings, valves and other accessories should be tested at 4 bar above the working pressure for two hours

Hydro static test

Fire fighting systems

Fire fighting system are classified into two main system

Manual Fire fighting system :

- Landing valve (L.V) - Fire Hose cabinet (F.H.C)

- Fire Hydrant (F.H)

- Fire Department Connection (F.D.C)

- Portable Fire Extinguishers

Stand pipe system

Landing valve (L.V)

A valv to control the water stream, located inside or outside the building

Fire Hose Cabinet (F.H.C)

A Fire hose is a high pressure hose that carries water to a fire to extinguish it

Where toplace (L.V) and F.H.C ?

F.H.C should be located at the following places:

- Exit stairs

- Entrance of buildings

- Garages entrances

- Wherever travel distance exceed (36 m) from anther (L.V) OR (F.H.C)

Fire Hose Cabinet Classes

Class (I) system

1 Comments

Excellent topic , go a head , we expect more from your valuable site

ReplyDelete